Electric heater is a kind of heating and temperature drop which is often used in industrial production and scientific research. During the heating process, it is often necessary to carry out various temperature control operations. With the development of computer application skills, the temperature control skills of electric heaters have also made great progress. Broadly divided into two broad categories.

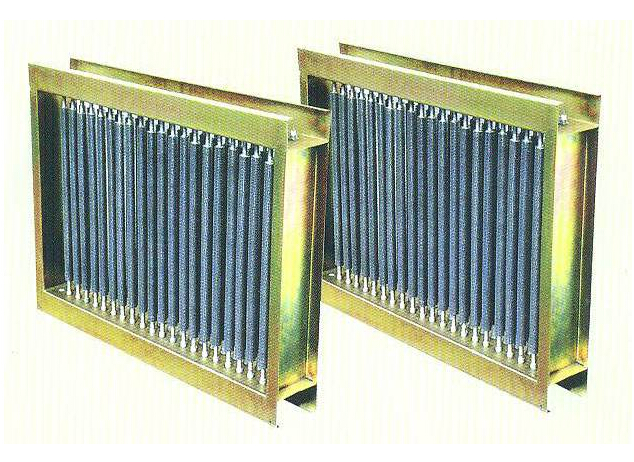

As shown in the first class plan. In fact, it was born out of the conventional appearance, that is, replacing the conditioning system in the exterior system with the badge system, and it can be said that it is a mixed system. Its primary advantage is that it is easy to connect with the external system, and easy to complete the switch between the table system and the badge system. This is beneficial for the transformation of the exterior system in the short run. However, there are significant drawbacks to such schemes as electric heaters. The first is the equipment used more system clutter. The cost is higher; secondly, because transform multi link output channel (especially after the analog conversion, so nonlinear interference is more serious, and the difference of energy control accuracy is low; third, system reliability is poor. As shown in the second class plan. In this scheme, the output end removed D/A transform, voltage signal expansion, high-voltage pulse signal transform link directly with the pulse signal TTL level to control the solid state relay, and a solid state relay to control the on-off of the electric heater. It can be said that this plan basically overcomes the defect of the first plan, give full play to the advantages of computer skills. The electric heater which can not only considerably reduce the cost, and can greatly improve the control precision (from room temperature to 720 DEG C, control precision is better than 0.5 DEG C). In addition, its anti-interference function and reliability are better than the first kind of plan.

Precautions for the use of air duct electric heaters, except for some common sense that we all know:

(1) the conditions for the use of electric heaters are as follows: the relative humidity of the air is not greater than 95%, and there is no explosive or corrosive substance or gas in the environment. The operating voltage shall not exceed 1.1 times the rated voltage, and the insulation resistance shall not be less than 1M ohms.

(2) the electric heating pipe in the electric heater should be fixed and fixed, and the effective heating area should be immersed in liquid or metal solid. No burning phenomenon is allowed, which will damage the electric heater.

(3) if there is scale on the surface of the pipe, or the phenomenon of carbon deposit occurs, then clean it immediately, so as not to affect the heat dissipation of the electric heating tube, thus affecting the service life of the electric heater.

(4) of the fusible metal, or solid salt, alkali, asphalt, paraffin and other heating, should use low voltage. When the medium is melted, the voltage is raised to the rated voltage.

(5) when heating the air, the components should be arranged evenly and evenly so that the components can be well protected by heat dissipation, and the air can be heated sufficiently.

(6) its wiring part should be outside the insulation layer, and to avoid moisture, the fastening screws should be avoided when the force is too strong.

Address: No. 3 Dazhai River Road, Baoying Development Zone, Yangzhou, Jiangsu, China

Tel: 0514-88603099 / 8860 0333 / 88600999

Fax: 0514-8860 0909 / 88913066

Technical support: 0514-8860 0808

E-mail: info@wnheater.com

URL: en.wnheater.com

| |

| Official website |