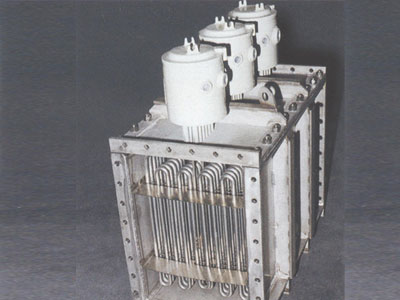

Duct type electric heater is mainly used for air heating specification in an air duct divided into low temperature, medium temperature and high temperature in three forms, in the common structure is made of steel plate supporting the electric heating tube to reduce the vibration of the electric heating pipe, are equipped with ultra temperature control device in the connection box. On the other hand except in control with over temperature protection, between the fan and the heater is still transport device, to ensure that the electric heater must start after the fan is started in a heater plus differential pressure device, to prevent machine fault, gas pressure passage heater generally should not exceed 0.3Kg/cm2, if you need more than pressure. Please use the circulation type electric heater; low temperature heater type gas heating temperature is less than 160 DEG C; medium temperature is less than 260 DEG C; high temperature does not exceed 500 degrees. The air duct type electric heater is used for industrial air duct, air conditioning duct and various industries. The air is heated by air to increase the temperature of the output air, and the air inlet is generally inserted in the transverse opening of the air duct. According to the operating temperature of the air duct, it can be divided into low temperature, medium temperature and high temperature. According to the wind speed in the air duct, the low wind speed, medium wind speed and high wind speed can be divided.

Air duct heater is a kind of equipment which is used more in work and life, such as electric stove, electric iron, electric iron, electric heater, electric oven and so on. They belong to electric heating equipment.

The resistance wire of the electric heater is made of nickel and chromium alloy, and the temperature is even higher than 800 DEG C. Because the electric heater power is relatively large, if the user ignores safety, fire may happen at any time. The causes of the fire in electric heaters are as follows: first, the electric heater is put on combustible or placed near combustible, and fire is caused by long time high temperature baking. Two, the electric heater is not installed plug, directly plug the wire head into the socket, so it is easy to cause short circuit and fire. Three is the use of electric heaters, the left of the electric heater plug is not drawn out, the time is too long, causing the electric heater overheating, the adjacent combustible ignited and cause fire. Four is the resistance wire, after many repairs continue to use, may cause the line overload to cause the fire.

The air duct electric heater is mainly used to heat the required air flow from the initial temperature to the required air temperature, up to 850 degrees centigrade. Has been widely used in aerospace, weapons industry, chemical industry and institutions of higher learning and many other research and production laboratory. It is especially suitable for automatic temperature control and large flow high temperature combined system and accessories test. The scope of use of electric air heater width: can heating of any gas, hot air generated by dry water, not conductive, no burning, no explosion, no chemical corrosion, no pollution, safety, fast heating heating space (controlled).

Characteristic:

The electric heating tube adopts an outer corrugated stainless steel band, which increases the radiating area and greatly improves the heat exchange efficiency.

The heater has reasonable design, small windage resistance, uniform heating, no high and low temperature dead corners.

Double protection, good safety performance. A thermostat and fuse are installed on the heater. It can be used to control the air temperature of the air duct. It can work safely without any wind.

Address: No. 3 Dazhai River Road, Baoying Development Zone, Yangzhou, Jiangsu, China

Tel: 0514-88603099 / 8860 0333 / 88600999

Fax: 0514-8860 0909 / 88913066

Technical support: 0514-8860 0808

E-mail: info@wnheater.com

URL: en.wnheater.com

| |

| Official website |